Products

Transformer Radiator Solutions

Key radiator types we manufacture for transformers and allied equipment.

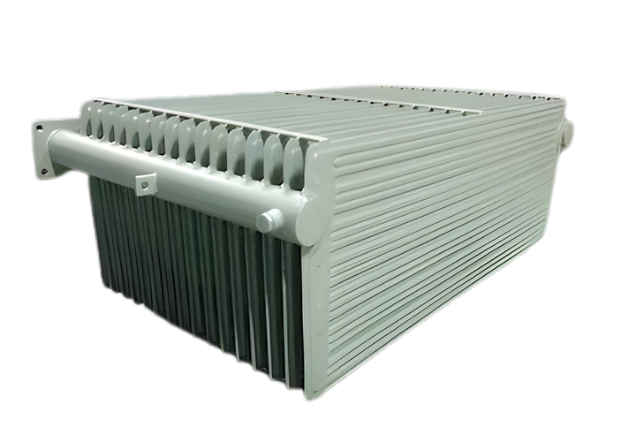

Welded Type Radiators

Heavy-duty welded radiators engineered for reliable cooling on power and distribution transformers.

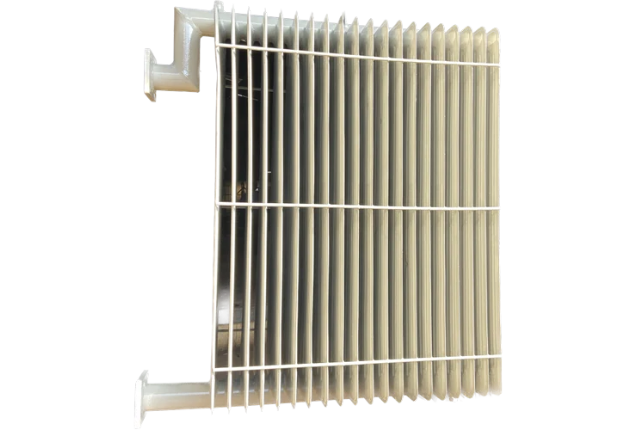

Flanged Type Radiators

Flanged radiators that allow easy mounting, removal and maintenance on the transformer tank.

Offset Radiators

Radiator assemblies designed to suit restricted clearances and special layouts.

Swan Neck Radiators

Curved swan-neck radiators that provide flexible oil connection routing and positioning.

Radiators With Graded Elements

Graded fin lengths that help optimise heat dissipation and oil circulation across the assembly.

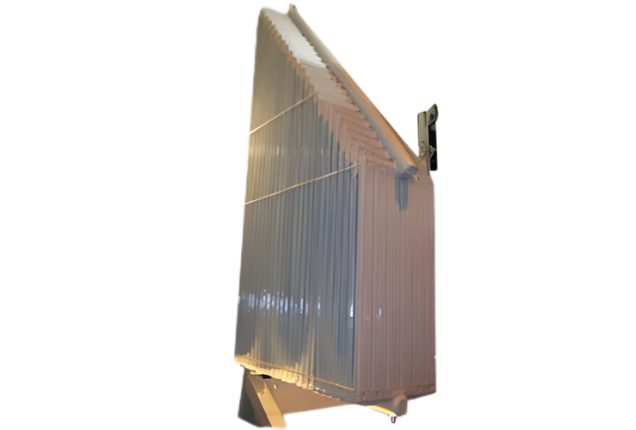

Radiators With Sloped Elements

Sloped element radiators engineered for better oil draining and cooling characteristics.

Radiators With Multiple Inlet & Outlets

Multi-inlet and outlet radiators that serve higher ratings and complex transformer designs.

TRANS-VOLT Steel Pressed Radiators

TRANS-VOLT manufactures pressed steel radiators for power and distribution transformers, designed for efficient oil cooling and long, reliable service. Our radiators are used on transformers, rectifiers, reactors and other oil-cooled equipment across a wide range of ratings.

We boost the energy by cooling the temperature.

The plant has a capacity to manufacture radiators with fin widths of 226 mm, 300 mm and 520 mm. Fins are manufactured with a pitch of 50 mm, in lengths from 400 mm to 4000 mm (in steps of 100 mm) and assemblies ranging from 2 to 30 fins as per customer requirements.

| Parameter | Range / Details |

|---|---|

| Fin Width | 226 mm, 300 mm, 520 mm |

| Fin Pitch | 50 mm |

| Fin Length | 400 mm to 4000 mm (in steps of 100 mm) |

| Number of Fins per Assembly | 2 fins to 30 fins |

| Application | Power transformers, distribution transformers, rectifiers, reactors and allied oil-cooled equipment |

Radiator Types Manufactured

- Welded Type Radiators

- Flanged Type Radiators

- Off-set Radiators

- Swan Neck Radiators

- Radiators with Graded Elements

- Radiators with Sloped Elements

- Radiators with Multiple Inlets & Outlets

- Pressed Steel Radiators for Power & Distribution Transformers

Radiator Range at a Glance

.png)

Welded Type Radiators

Flanged Type Radiators

Off-set Radiators

Swan Neck Radiators

Radiators with Graded Elements

Radiators with Sloped Elements

Radiators with Multiple Inlets & Outlets

Overall Manufacturing Capability

| Parameter | Range / Details |

|---|---|

| Fin Width | 226 mm, 300 mm, 520 mm |

| Fin Pitch | 50 mm |

| Fin Length | 400 mm to 4000 mm (in steps of 100 mm) |

| Number of Fins per Assembly | 2 fins to 30 fins |

| Application | Power transformers, distribution transformers, rectifiers, reactors and allied oil-cooled equipment |

Aesthetics and Surface Protection

Each radiator is finished with a robust internal and external coating system designed to protect against corrosion and extend service life.

- Inner surface coated with approximately 10 micron thick varnish to Class "A" as per IS 10026 – 1983.

- Outer surface blast-cleaned and spray-painted with primer and two coats of high-grade red oxide zinc-chrome as per IS 2074.

- Final finish paint supplied as per client requirements; alternate primer and finish systems available on request.

Quality Assurance & Testing

The company is strongly committed to quality and customer service, with a clear aim to be regarded as the best in its business. Every radiator is manufactured under controlled processes and individually tested.

- Comprehensive dimensional checks for each radiator assembly.

- Each radiator individually air-pressure tested at approx. 2.5 kg/cm2 under water for at least 30 minutes.

- Testing practices aligned with relevant industry standards such as IEEMA specifications.

Why Choose TRANS-VOLT Radiators?

Our journey is driven by Total Quality Management — fully satisfying our customers' requirements through continuous improvement. TRANS-VOLT radiators are engineered to optimise heat transfer, mechanical strength and appearance, ensuring a dependable cooling system for your transformers.

Manufacturing Highlights

Plant located at Pirangut Industrial Area near Pune, equipped with a modern manufacturing line, tools and test equipment to produce high-quality transformer radiators.

Need a Custom Design?

TRANS-VOLT can engineer radiator configurations tailored to your transformer rating, cooling requirements and site conditions. Share your drawings or specifications, and our team will support you with an optimised solution.

Contact Sales